Increase Efficiency with RF Picking Technology

Order picking is the process of retrieving a set amount of products from warehouse inventory to fulfill customer orders. The vast majority of picking is done by human workers using paper-based picking lists. This increases the likelihood of errors which can be costly, wasting time and money.

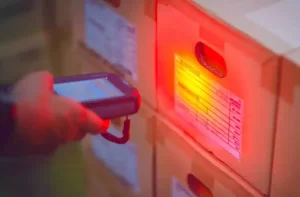

As a result, Radio Frequency (RF) Scanners are gaining popularity to reduce the chance of costly errors in the fulfillment process. These scanners direct workers to the correct pick location and provides the quantity to pick and item location. These tools can be wearable or handheld devices.

Handheld Scanners for small businesses

How It Works

The radio frequency handheld scanner is used to read the barcode, transmit product information and location information to the wireless WMS network. Afterward, this data is sent to the radio frequency terminal where the warehouse operator (or picker) uses the radio frequency gun. The RF device sends the picker to the correct location and delivers the item description and the quantity to be collected.

Wireless scanners scan the barcode of the product and, if necessary, the pick-up location. Compared to paper-based picking, the RF technology generates a reliable system that guides the process through barcode scanning and confirmation of the location of a product before it is picked up and shipped to the warehouse. For the pick-up task to be downloaded into the system, a light is displayed so that workers know where to go.

A WMS-controlled RF system adds a data input to the barcode scanning process that does not require the paper-based process and adds a second pick transaction. As a result, voice-controlled workers can dial 15-35% faster with an RF scanner. RF scanners are often used in the workflow of bearings because they can capture product and customer-specific information such as batch numbers, serial numbers, catch weights, etc.

Why RF Picking is More Efficient Than Paper

The transition from paper-based systems to RF scanning can result in up to 20% productivity loss due to interaction with the device. Simple errors can occur when scanning the items including selecting the wrong product or scanning the wrong barcode label can occur. Errors can occur if the barcode is missing or damaged, the operator scans the wrong product, selects the wrong quantity, or misplaces the device.

Many distribution centers and warehouses use picking solutions that combine both voice and RF scanning. When it comes to order fulfillment technology, distribution center employees often have RF scanners, voice-controlled work systems or a combination of the two. Today, RF is widely used in integration with warehouse software and barcode networks.

Why RF Picking Technology is Becoming More Widespread

The widespread use of mobile devices in warehouses means that RF speed and accuracy can be applied to more activities generating more information about your business, your employees, and your profitability. RFID is finding its way into more and more warehouse environments, and in today’s warehouses, RF technology is being used to improve accuracy, increase productivity, and increase customer satisfaction.

Your WMS records the date, time and RF scan in a specific order. With the priority scan and “do not disturb,” you can set the priority function so that channels are checked every 2 seconds, even if the scanner does not receive any transmissions. When in lock mode, you can set your scanner to skip certain frequencies and channels when scanning or searching.

A RF pick-up system is a host server that communicates with higher levels of the Warehouse Management System (WMS) and Warehouse Execution System (our Warehouse Control System) to send and receive order information. An RF device that scans radio frequencies and adjusts them to the desired frequency is similar to the barcode scanner used in storage, but uses radio frequencies for its operation.

A warehouse can set up a radio frequency scanner, a handheld wireless device that uses a high-frequency wireless network to communicate with the WMS to transmit real-time information over the network.

The device is an RFID reader, just like an RF scanner, which scans the information contained in the RFID quick tag. According to Lucasware.com, “Voice-picked systems are used in 20-25% of warehouses and distribution centers, but the vast majority of warehouses rely on the paper or mobile barcode scanning technology (also known as RF scanning systems) for picking and other material handling tasks.” As with the hand-held RF scanners, the workers positioned the device by clamping it under their arms to free their hands to perform the recording.

0 Comments