Motorized Roller Conveyors can help save you valuable time and money

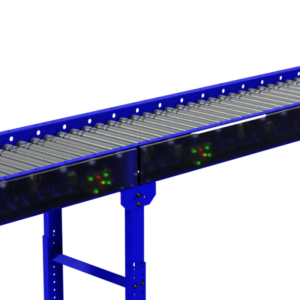

Motorized roller conveyors are a type of material handling conveyor. An electric motor (often called an MDR motor) powers the rollers to move products quickly along the conveyor line.

Powered roller conveyors use 24 volt DC motorized rollers to control the movement of products. These conveyors are ideal for heavy duty applications and can handle loads up to 2000 lbs. per roller.

Live Roller Conveyors use a series of powered rollers that are in line with each other. The rollers are powered by an electric motor which turns the rollers and moves the product down the line.

Motorized conveyors have control zones. These zones are controlled by controller cards. The cards can be connected together via a plug and play interface. This interface is used to control the speed and direction of the conveyor.

The control zones are usually located at the beginning and end of the conveyor. The control zone at the front of the conveyor is used to start and stop the conveyor. The control zone at the end of the conveyor is used to reverse the direction of the conveyor.

How they work:

Motorized driven conveyors are powered by an electric motor. The motor turns a pulley or gears, which then move the belt or chain on which the product is moving. Motorized driven conveyors come in many different types, including:

-

- Roller conveyors

- Belt conveyors

- Chain conveyors

- Screw conveyors

- Bucket elevators

Powered roller conveyors are one of the most versatile and economical types of motorized driven conveyors.

They can be used for a wide variety of applications such as:

-

- Assembly lines

- Sorting and picking lines

- Packaging lines

- Shipping and receiving lines

Powered roller conveyors are also used in many industrial applications such as:

-

- Manufacturing

- Warehousing

- Distribution

Why Choose a Motor Driven Roller Conveyor System?

Existing conveyor systems can be enhanced with powered roller conveyors to improve performance. A driven roller conveyor system uses a motor to drive one or more rollers, which in turn powers the belt or chain that transports the product.

This type of system is often used in assembly lines and other high-speed applications where precise control and synchronization are required. Conveyor systems incorporating powered rollers can also be adapted to handle a broader range of products, including oddly shaped or heavy items. As a result, it is an essential tool for manufacturers looking to increase efficiency and productivity.

Powered roller conveyors offer many advantages over traditional conveyor systems. They are more energy efficient because the powered rollers only need to be powered. In addition, they provide greater control and accuracy, which is essential in applications where product placement is critical. Finally, they are easier to maintain and can be easily expanded or reconfigured to accommodate changing needs.

How Russell Conveyor can help

Whether you are looking to improve existing conveyor system or design a new one, powered roller conveyors should be considered an essential part of the equation. Their many benefits make them a powerful solution for a wide range of industries and applications.

Powered roller conveyors are an excellent solution for a wide range of manufacturing applications. They offer many advantages over traditional conveyor systems, including increased energy efficiency, greater control and accuracy, and easy expandability. If you are looking to improve your existing conveyor system or design a new one, powered roller conveyors should be a key part of your planning.

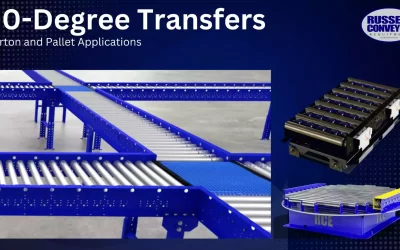

At Russell Conveyor & Equipment, we can help you choose the best conveyor option for your warehouse. We offer system design and engineering services as well as installation. We can even retrofit older systems to help save time and money. We are here to help! Give us a call today!

0 Comments