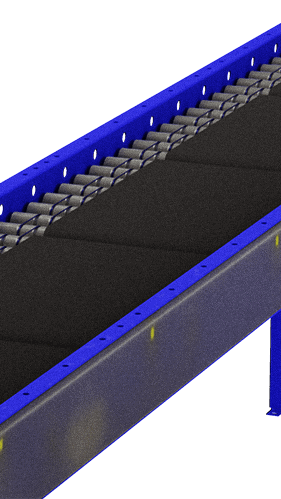

MDR Accumulation Conveyor systems hold products in zones to give you a steady flow of product downstream

An MDR accumulation conveyor is a system used to control the flow of products along a production line. By using a series of rollers or wheels, the conveyor can accumulate and release products at a controlled rate. This type of conveyor is often used in manufacturing and assembly applications.

MDR Accumulation conveyor systems or slug conveyors use powered rollers to temporarily stop or hold material during the fulfillment process. This is important to reduce or stop damage to lightweight or fragile packages due to pressure build-up. Case accumulation conveyors can provide zero pressure which keeps the packages from touching or minimum pressure which allows light touching.

Accumulation conveyors are versatile and essential components of modern material handling systems, with different types playing an important role.

Zero pressure accumulation conveyors are designed to temporarily store products for short periods. This makes them ideal where there needs to be a pause between production steps for any reason, or when transporting items through multiple locations safely.

Minimal pressure accumulation conveyors use speed control to stack items in layers so they can move through an automated system without the risk of shifting.

Each type of accumulation conveyor offers a unique set of benefits and should be chosen according to specific needs.

Pressure accumulating conveyors can be useful in high-volume facilities where products of different sizes and weights are being handled and/or shipped.

Often, when packages back up on the conveyor system, the larger packages can damage or crush the smaller ones. With our live roller conveyor, we install controllable zones where photo eyes detect package build-up and the conveyor shuts off, thus saving energy. The pre-wired system then powers back on when packages have moved down the line. The drive rollers can hold or buffer the products into areas for palletizing, high-speed sorting, or merging.

Features of MDR accumulation systems:

- 50% more energy-efficient than traditional conveyor systems

- Quiet operation

- Easy start-up and maintenance

- Increased safety for operators

- Lower maintenance costs due to the lack of extra parts

- Easier programming abilities making changeovers more efficient

Zero-Pressure Accumulation

Zero-pressure accumulation (ZPA) is a specialized motor-driven roller (MDR) conveyor where a conveyor belt stops cartons or packages for a set amount of time so they can be collected. This allows them to accumulate without touching, reducing the potential for damage as the cartons proceed to the next location. The MDR Accumulation roller conveyor works like a four-way stoplight at an intersection. The MDR processes each product to ensure it goes to the right place as safely as possible.

This reduces damage and saves energy. This conveyor system uses zones to communicate with the other zones within the conveyor line. Each zone operates independently but continues to communicate with one another via an internal network infrastructure and controller cards. Every station produces the desired accumulation method needed to operate effectively.

Minimum pressure accumulation allows cartons to touch one another. The conveyor will shut off when there is a certain amount of pressure, reducing damage to accumulated products.

Accumulation Tables & Buffer Zones

An accumulation table is a conveyor system that is used to store products or materials in a temporary holding area. The accumulation table typically has a series of rollers or wheels that rotate to move the product along the table. When the accumulation table is full, the products or materials are then moved to another area for further processing or storage. Accumulation tables and buffer zones help with product flow and line accumulation.

Accumulation tables are a type of buffer zone that are used to prevent the accumulation of material at specific points along a conveyor belt. They are typically used in factory or production settings where it is important to keep the flow of material moving smoothly.

An accumulation table is a simple, flat surface that extends out from the conveyor belt. It helps keep the material moving forward by providing a place to accumulate, rather than building up at the end of the belt. This prevents jams and keeps the line running smoothly.

Buffer zones are an essential part of any conveyor system. They help to ensure that the material moves along at a consistent pace, and they also protect the equipment from damage. Accumulation tables are a simple, yet effective, way to create a buffer zone. By keeping the material moving forward, they help to prevent accumulation and keep the line running smoothly.

Accumulation Conveyor Pros:

Product accumulation is an important part of many production lines. By using an accumulation conveyor, manufacturers can ensure that products are released single file, at the proper rate, and that the production line runs smoothly.

For applications requiring maximum accumulation, the accumulation conveyors offer control and flexibility. Motorized rollers enable powered zones of multiple lengths, while advanced options allow for zero-contact Accumulation.

Conveyor accumulation can be a challenge for industrial facilities. By understanding the material handling needs of your facility, you can develop a system that keeps your operation running smoothly.

We offer many conveyor specifications, and we customize the conveyor line based on your individual needs. Depending upon the conveying application, different controls and accessories are available. Let us help you decide the right solution for your business needs.