Implementing a 90-Degree Transfer Conveyor: The Key to a Superior Material Handling Conveyor System

Material handling technology has transformed the way companies move their products within their facilities. Material handling equipment has become an essential aspect of many industries, from manufacturing to retail. With the growth rate of a CAGR of 5.7% by 2030 this market is showing no signs of slowing down.

It involves the movement, storage, control, and protection of materials and products throughout the supply chain. There are various conveyor types available such as roller conveyors, belt transfers, chain transfers, and automated conveyor systems that can assist in transferring products from one point to another.

Belted conveyors and conveyor lines are also popular material handling solutions for distribution centers and warehouses.

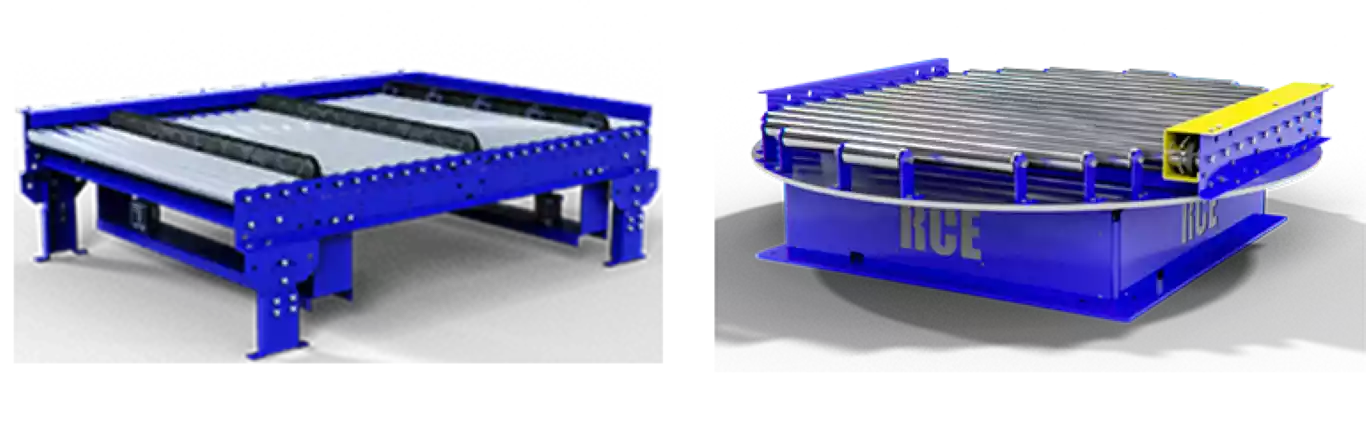

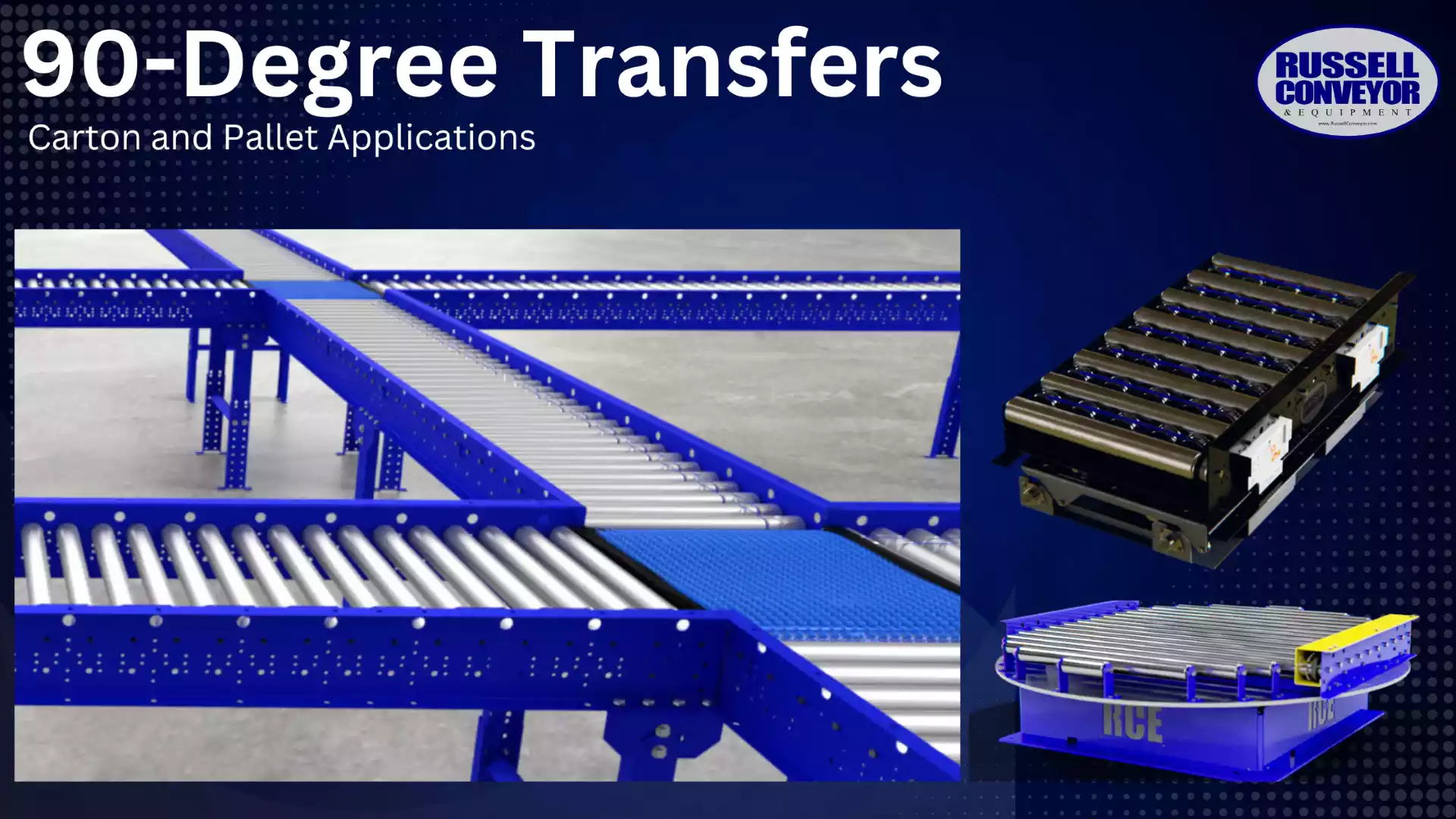

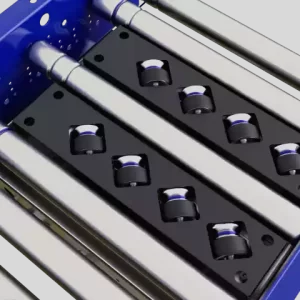

However, when it comes to transferring products at 90-degree angles, conveyor transfer solutions are necessary. 90-degree transfers are ideal for moving products in and out of assembly lines, inspection areas, and packaging stations. Conveyor types like chain transfers and belted conveyors are widely used in these situations.

A wide range of conveyor types and conveyor transfer solutions are available to meet the specific needs of different industries. Companies can choose from various conveyor systems and material handling equipment to find the perfect solution for their specific requirements.

Adding 90-degree transfers, into a material handling system can provide numerous benefits, such as increased efficiency, improved safety, and cost savings.

Visit our Online Store

View this item and other related items in our online store.

Frequently asked questions

Got questions? Check out our frequently asked questions for answers!

0 Comments